| Material | PLA | ABS | PETG | Nylon | TPU |

|---|---|---|---|---|---|

| Cost | ★ | ★ | ★★ | ★★★★ | ★★★★ |

| Strength | ★★ | ★★★ | ★★ | ★★★★ | ★★★ |

| Detail | ★★★★ | ★★ | ★★★ | ★★ | ★★★ |

| Durability | ★★ | ★★★ | ★★★ | ★★★ | ★★ |

| Flexibility | ★ | ★★ | ★ | ★★★ | ★★★★ |

| Temperature Resistance | ★ | ★★★ | ★★ | ★ | ★ |

| Print Difficulty | ★ | ★★★ | ★★ | ★★★★ | ★★★ |

| Finish | Matt | Matt | Gloss | Semi-Gloss | Gloss |

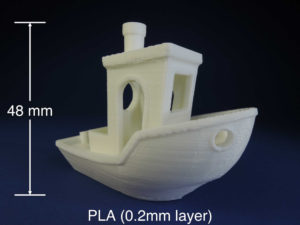

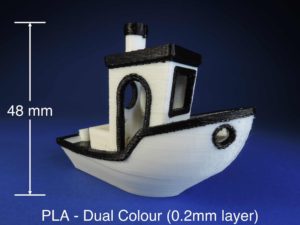

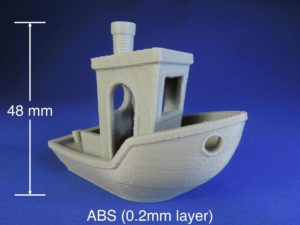

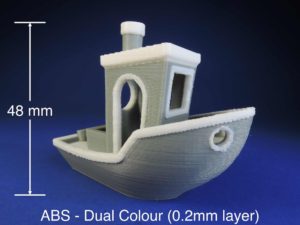

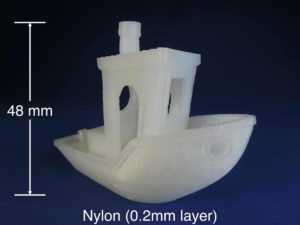

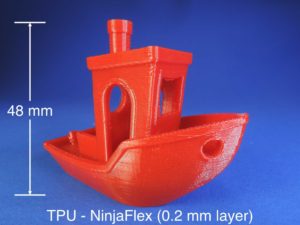

Photos of 3DBenchies printed in each type of material below.

What is a 3DBenchy? A 3DBenchy is a 3D printing torture test which has become somewhat of an industry standard to gauge quality of printers and materials. The design while cute contains many elements that are difficult to print such as overhangs (bow, side door arches), bridging (front window top edge) and tolerances (vertical and horizontal holes and boxes). For more information see www.3dbenchy.com

PLA (Polylactic Acid)

Goto material for hobbyists for ease of printing.

PROs: Lowest cost easy to print material for high detail prints. Good for large prints.

CONs: Brittle, and not as strong as other materials. Not suitable for higher temperatures. Not suitable for automotive applications as it can deform in the interior on a hot day.

ABS (Acrylonitrile Butadiene Styrene)

Traditional material first used for 3D printing. Plastic best known as being used in Lego bricks.

PROs: Lowest cost and can withstand higher temperatures suitable for use in automotive applications. Strong and somewhat flexible suitable for parts that snap together. Can be machined, glued and painted.

CONs: Challenging to print due to shrinking when it cools. For best results must be printed in a heated enclosure to minimize warping.

PETG (Polyethylene Terephthalate Glycol-modified)

Newer 3D printing material commonly used in disposable drink bottles. Provides a good compromise between the ease of PLA printing and strength and temperature tolerance of ABS.

PROS: Low cost easy to print with. Suitable for higher temperature applications. Stronger than PLA.

CONS: Somewhat brittle. Difficult to paint or glue.

Nylon (Polyamide)

Best for mechanical moving parts as it is strong and low friction. Best known as material commonly used for zip ties. Can actually 3D print them!

PROS: Strong, low friction, higher temperature tolerance. Machinable with some flexibility.

CONS: Difficult to print. Like ABS will shrink as it cools. Requires high temperature extruder and heated print enclosure to minimize warping. Absorbs moisture requiring special print handling and not suitable for outdoor applications. Somewhat expensive.

TPU (Thermoplastic Polyurethane)

Very flexible rubber like material. Great for model tires, seals and waterproof enclosures.

PROS: Strong and very flexible.

CONS: Expensive. Doesn’t bridge well.